About Rollforming Machines

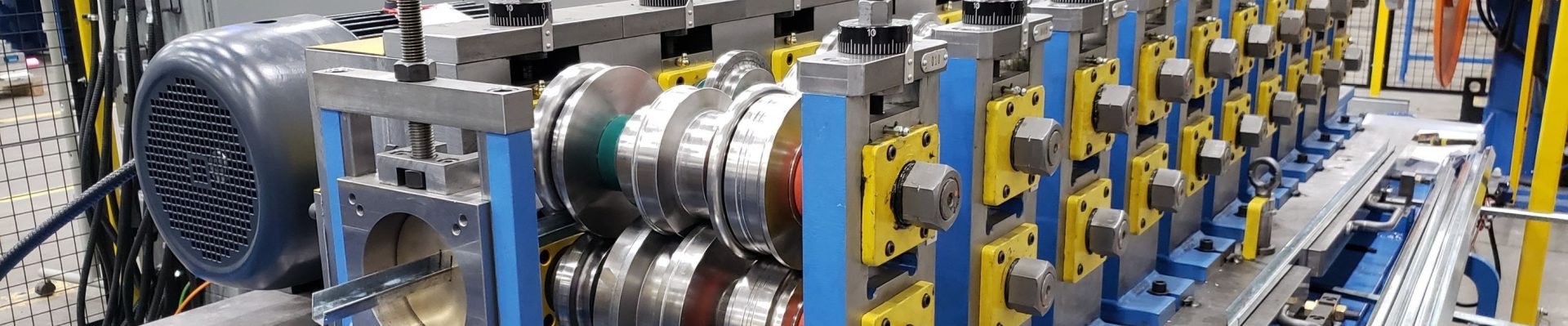

Studmaker™ Rollformer

One machine – designed to do it all!

Samco Machinery Ltd. keeps stud producers in the forefront of rollforming technology- to meet the overwhelming requirements of commercial and residential markets.

The Studmaker™ allows you to offer clients 24-hour custom stud service on various gauges of material. This includes different widths and flange height combinations, plus the rollforming of deep leg tracks without single shear dies.

Advantages

Studmaker™ rollforming equipment can be changed in 20 minutes or less to produce different width and flange heights in different gauges of material.

An electro-mechanical adjustment is all that’s required to offer a wide range of stud and track widths on demand. With the Studmaker™, you can produce studs and tracks in a wide range of material gauges and lip sizes from 3/8” to 5/8” as gauge and standards require.

The Studmaker™ can replace outdated rollformers that hold your production with their lengthy changeover times. It can also be matched with your existing pierce and cut-off equipment to minimize cost.