About Material Handling Solutions

Samco is well known for the packaging equipment that accompanies their rollforming systems.

Focus: Samco’s Master Bundler

Master Bundlers packaging automation machine makes mini bundles and automatically builds pre-programmed master bundles, effectively reducing the labor of two operators from each rollforming line (at production speeds of 500 ft per min and more).

The material handling equipment has been designed to permit the rollforming line to operate continuously, building the succeeding master bundle, while the completed mater bundle moves to the second stage banding position. There is no stopping of the rollforming line while the completed master bundle is moved to the second stage position.

The fast payback on Master Bundler packing equipment makes cost justification an easy one to document. With over one hundred Samco Master Bundlers in operation, this packing equipment has earned its reputation – for reducing labor costs, and for fewer worker compensation claims.

Watch Samco Machinery’s Strut Packaging System

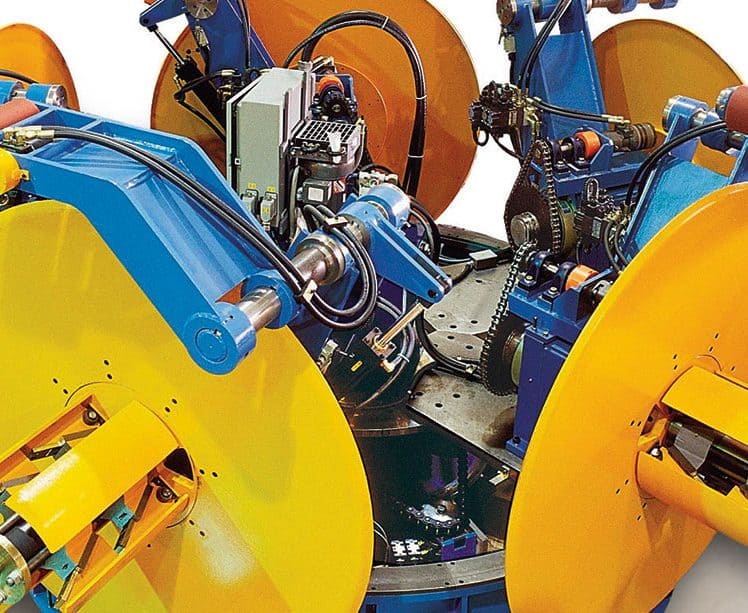

Uncoilers

Samco initially manufactured uncoilers for the tube mill and rollforming industry more than 35 years ago. Today, the company offers innovation and design of complete rollforming material handling equipment and uncoilers for the automotive, shelving and racking, building construction and stud and track industries. Uncoilers are designed to withstand tube mill speeds of up to 1,000 feet per minute. Uncoilers and coil car combinations are engineered to suit a unique application for each customer. (Key Efficiency: Your line becomes more productive when you employ proper coil handling procedures, therefore creating less downtime.)

Learn more about Uncoilers here.

Slitters

Samco slitting lines are designed to handle a wide array of materials. Either driven or pull-through, the interchangeable machine permits off-line setups and includes strip tensioners and oscillating rewinders. (Key Efficiency: Incorporating coil slitting as part of your production capability line reduces waste and can be more economical.)

Bundlers

Master bundler machines bundle the nestled stud when it comes off the rollformer and comes with automated strapping. This material handling equipment automates the handling of mini-bundles and automatically builds pre-programed master bundles. (Efficiency: Bundlers effectively reduce the labor of two operators from each rollforming line at production speeds that can exceed 500 feet per minute.)

Stackers

Roof or wall panel stackers do just that: stack panels at the end of the rollforming line. The rollforming material handling equipment are programmed to move the stack of panels at a pre-determined number of panels and then moves the stack to an area for pickup by a forklift. (Key Efficiency: Stackers allow for maximum run speeds and eliminate the need to have operators manually gather and stack panels as they come off the line.)

Nesters

Nesters for the stud and track industry handle product as it comes off the line up to 500 feet per minute. As the name suggests, it nest studs for safe and efficient moving or packing and shipment. (Key Efficiency: Similar to stackers, the nesters eliminate the need for multiple workers at the end of the rollforming line, providing a safer and more efficient work environment.)