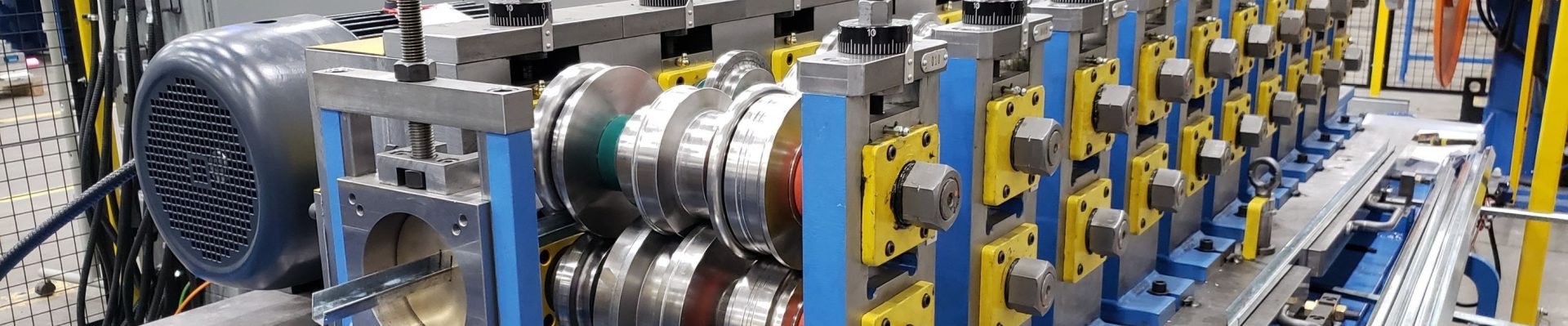

About Rollforming Machines

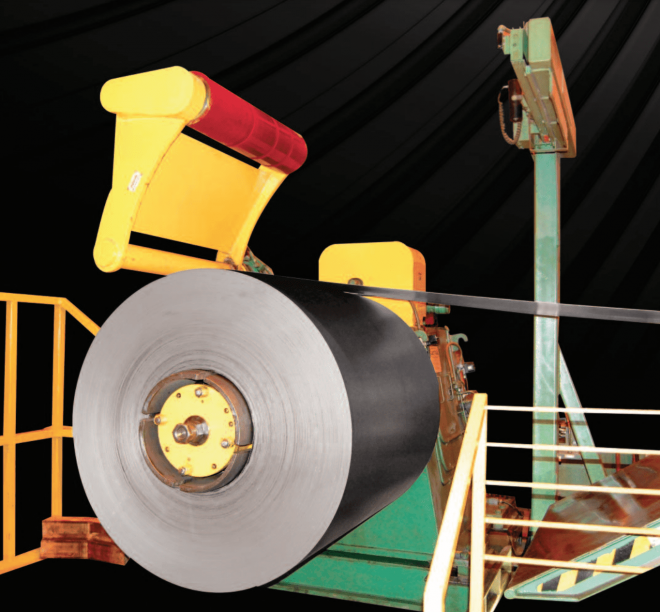

Coil Processing

Specializing in strip and flat rolled steel process equipment, coil and sheet handling equipment, and slitter tooling and shear blades, Samco offers coil processing equipment, including:

Cut to Length

Samco has made great strides in producing precision cut-to-length lines. These are designed to produce cut-to-length blanks from coils at a maximum speed of 400 fpm (120m/min).

The prime application for this type of equipment would require materials having a thickness of less than .035″ (8mm).

Tension level flat precision blanks or sheets are produced in one operation.

Blanking

Samco’s precision blanking lines produce cut-to-length blanks from a variety of coil weights up to a maximum of 40,000 lbs. Roll feed lines are capable of 400 fpm with a production rate of 60 pieces per minute.

Blanking and Sheeting lines are capable of consistently producing length accuracies of +/- 1/64″ (+/- .3mm). Automatic air flow stacking systems prevent sheet surface damage.

Other features include:

- Length tolerance of +/- 1/64″ (+/-.3mm) and a squareness of 1/32″ (.8mm).

- Thickness range of 0.15 – .125″ (.3mm – 3.17mm).

- Hump type lines with capacities up to 72″ (1850mm) wide and 1/4″ (6.3mm) thickness.

Slitting

Slitting lines are designed to handle extreme ranges of materials. Either driven or pull through, this interchangeable machine permits off-line set ups and includes strip tensioners and oscillating rewinders.

Key features include:

- Slitting lines for ferous and non-ferous strips.

- Handling a maximimum coil weight of 60,000 lbs (30,000 kg).

- Handling a maximum coil width of 100″ (2.5 metres).

- Minimum thickness .001″ (0.25mm) to .375″ (10mm).

- Running speeds of up to 1500 fpm (500m /min).

- Strip width tolerance of .001″ (0.25mm).